Optimizing Machinery Long Life: Purchasing Costs Undercarriage Parts Solutions

Optimizing Machinery Long Life: Purchasing Costs Undercarriage Parts Solutions

Blog Article

Necessary Overview to Undercarriage Parts for Heavy Equipment

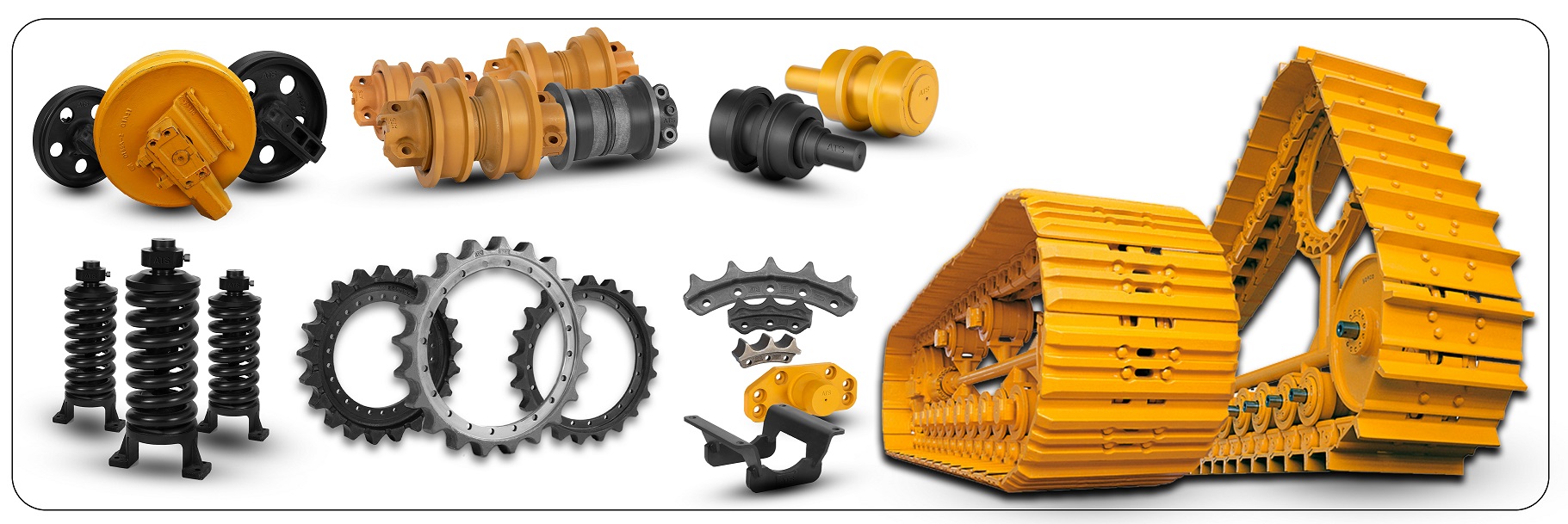

When it concerns heavy tools, the undercarriage plays a critical function in making sure effective and smooth procedures. Comprehending the elaborate details of undercarriage parts is vital for taking full advantage of the lifespan and efficiency of your machinery. From track chains to idlers and rollers, each element adds to the total performance of the equipment. Diving into the specifics of sprockets and various other undercarriage aspects provides very useful insights into upkeep methods that can significantly affect the longevity of your hefty equipment. By grasping the significance of these components and their maintenance demands, drivers can optimize the efficiency and toughness of their devices, ultimately causing set you back savings and boosted operational effectiveness.

Significance of Undercarriage Parts

Recognizing the vital duty that undercarriage components play in the efficiency and long life of hefty equipment is vital for reliable upkeep and procedure - undercarriage parts. The undercarriage parts create the structure on which the whole device operates, supporting the weight of the equipment, providing stability, and absorbing shock loads during procedure. A well-maintained undercarriage not only makes sure smooth procedure however likewise contributes considerably to reducing downtime and repair costs

The undercarriage includes numerous crucial parts such as track chains, track footwear, gears, idlers, rollers, and track structures. Each of these parts plays an essential function in the general capability of the tools. As an example, the track chains and track shoes aid in giving grip and assistance, while the idlers and sprockets assist in driving the tracks efficiently. Normal examination, timely maintenance, and substitute of worn-out undercarriage parts are critical to avoid break downs and make the most of the life-span of the hefty tools. Fundamentally, purchasing high-quality undercarriage components and ensuring their correct treatment is important for optimum efficiency and longevity of hefty equipment.

Sorts Of Track Chains

Track chains are crucial elements of heavy tools undercarriages, providing the required traction and assistance for efficient operation. There are primarily two sorts of track chains utilized in hefty tools: sealed and oiled track chains (SALT) and completely dry track chains. Sealed and oiled track chains are generally discovered in contemporary hefty equipment. These chains are pre-lubricated and secured to stop dirt, particles, and dampness from getting in the chain joints, making sure smooth operation and prolonging the chain's lifespan. On the various other hand, dry track chains call for regular hands-on lubrication to keep optimal performance and stop early wear.

Role of Rollers and Idlers

Rollers and idlers play an important role in sustaining and assisting the track chains of heavy tools undercarriages, adding to the total security and performance of the machinery. Rollers are made to sustain the weight of the devices and supply a smooth surface for the track chain to move along. They aid disperse the weight equally, reducing excessive wear on the track chain and making sure correct traction. Idlers, on the various other hand, guide the track chain and aid keep proper stress throughout her explanation the undercarriage system. By directing the track chain in a controlled way, idlers prevent excessive side-to-side movement, lowering the danger of derailment and irregular wear.

With each other, rollers and idlers work in consistency to ensure that the track chain remains in location, even on harsh surface, enhancing the tools's efficiency and longevity. Appropriate maintenance and routine examination of rollers and idlers are vital to stop early wear and potential breakdowns, inevitably optimizing the efficiency and life-span of heavy devices undercarriages.

Recognizing Sprockets

One critical aspect of gears is making sure correct placement and tension to stop early wear and damages. Misaligned sprockets can cause irregular endure this website the track chain, causing reduced efficiency and possible security threats. Regular maintenance and inspection of sprockets are vital to identify any type of signs of wear or imbalance quickly.

Furthermore, gears can be found in numerous dimensions and tooth configurations, relying on the specific heavy devices and its intended usage. Appropriate choice of gears based on the equipment's specifications is vital to make sure optimum efficiency and durability of the undercarriage system. Understanding the duty of gears and their maintenance needs is essential for taking full advantage of the effectiveness and life expectancy of hefty devices undercarriages.

Upkeep Tips for Durability

To make sure the long term longevity and optimal functionality of heavy devices undercarriages, attentive maintenance practices are vital. On a regular basis checking undercarriage components such as track footwear, rollers, idlers, and gears for damage is important. Change any worn or damaged components without delay to stop more damage to the undercarriage system. Appropriate track stress adjustment is also essential for lowering early endure undercarriage parts. Over-tensioning can lead to enhanced anxiety on the parts, while under-tensioning can trigger track slippage and increased wear. In addition, keeping the undercarriage clean from debris build-up, mud, and various other pollutants can aid avoid deterioration and expand the lifespan of the components. Oiling the undercarriage parts at recommended periods will also reduce rubbing and wear. Finally, scheduling routine upkeep checks with skilled professionals can recognize prospective problems at an early stage and resolve them before they escalate, eventually optimizing the durability of heavy tools undercarriages.

Verdict

In conclusion, undercarriage components are vital parts for hefty devices, playing essential duties in preserving stability and capability. Understanding the different kinds of track chains, idlers, sprockets, and rollers is very important for correct upkeep and longevity of the tools. By adhering to maintenance suggestions and frequently checking and changing worn parts, operators can make sure the optimal performance and efficiency of their hefty machinery. Correct treatment and focus to undercarriage components are vital to making best use of devices lifespan and performance.

The undercarriage consists of different necessary components such as track chains, track shoes, gears, idlers, rollers, and track frames. The track chains and track shoes assist in offering grip and assistance, while the idlers and sprockets assist in driving the tracks efficiently (undercarriage parts). There are primarily 2 kinds of track chains utilized in hefty tools: sealed and lubed track chains (SALT) and dry track chains. Appropriate option and maintenance of track chains are critical to make sure the general performance and longevity of heavy devices undercarriages

Sprockets are essential elements of heavy tools undercarriages, accountable for moving power from the equipment to the track chain.

Report this page